MITIS, entreprise de technologies innovantes installée depuis 2012 à Bouguenais (Nantes), est la référence du procédé de Perçage Vibratoire, solution d’excellence pour optimiser les performances en production d’usinage.

New reference in drilling, a major asset for Industry 4.0

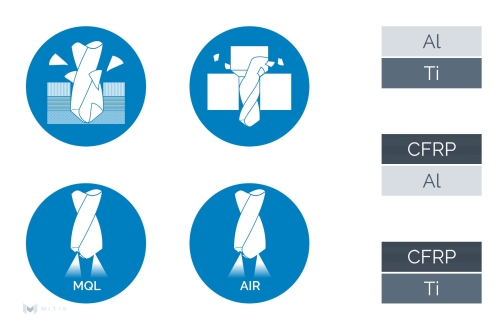

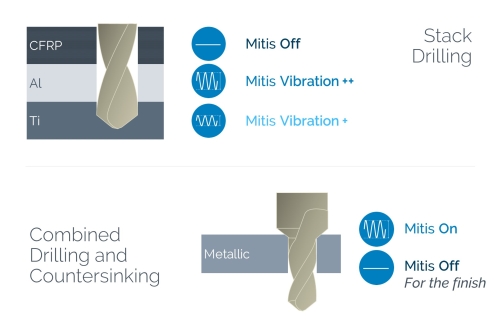

Maximum efficiency in complex multi-material stacks (frame assembly)

Vibratory assistance – Process monitoring

Drilling diameters

Dimensions compatible with market standards, fully integrated “MS Drive” control system: easy installation in automated systems.

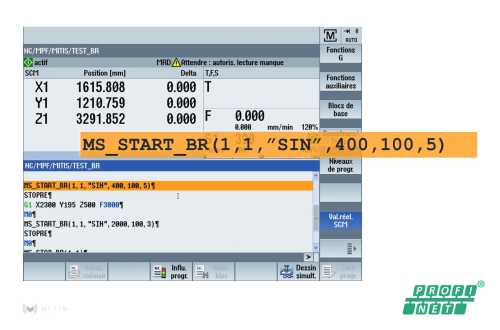

1 single command line in the ISO program to control the vibration parameters.

The vibratory assistance adapted in an instant to each step of the drilling / countersinking process.

Power supply for piezoelectric actuators, conditioning of process sensors, control and communication module

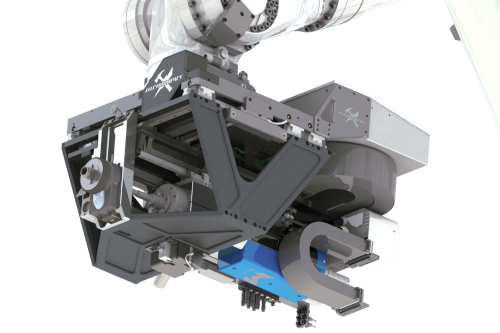

Integration of the MS1215 piezoelectric spindle into an aerospace drilling robotic end-effector (Loxin “Accurate Drilling Head”).

Controlling the MS1215 spindle in the Siemens 840D NC environment.

Piezoelectric Vibratory Drilling: the genesis of the development of the MS1215 spindle.

You want to know more about the MS1215 spindle and the piezoelectric technology?

Contact us at +33 2 40 59 24 21 or leave us a message:

MITIS, entreprise de technologies innovantes installée depuis 2012 à Bouguenais (Nantes), est la référence du procédé de Perçage Vibratoire, solution d’excellence pour optimiser les performances en production d’usinage.