MITIS, entreprise de technologies innovantes installée depuis 2012 à Bouguenais (Nantes), est la référence du procédé de Perçage Vibratoire, solution d’excellence pour optimiser les performances en production d’usinage.

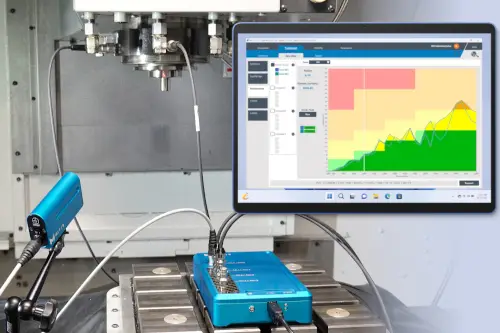

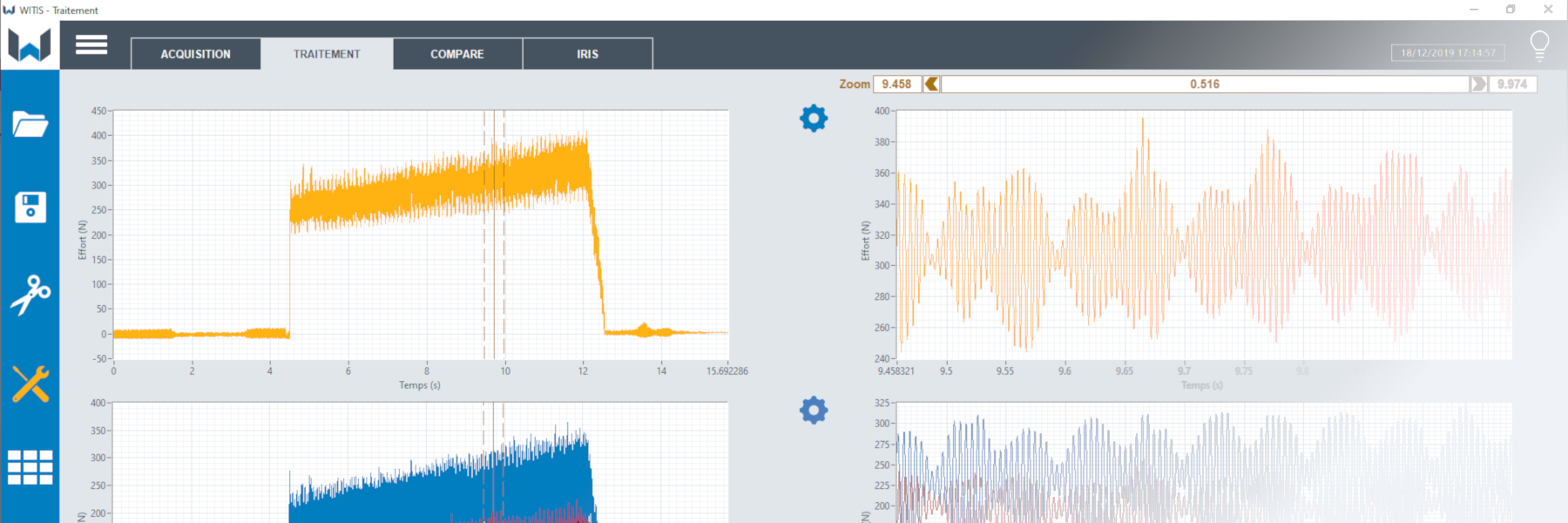

The performance of machining processes depends on defining the best cutting conditions, but also on ensuring that machine-tools or spindles are working properly. Physical measurement of cutting tool or machine behavior is now recognized as best practice for cutting optimization and machining equipment maintenance.

For more than fifteen years, our teams have been developing real expertise in this field: measurement of cutting forces to improve machining conditions, vibration diagnostics for spindle maintenance, vibratory analysis of the machining system, and so on.

Building on this experience, MITIS offers 4.0 applications for better machining control.

Simple, effective, expert.

Get more efficient control and preventive maintenance for the spindles of your machine tools.

IRIS, a portable vibration diagnostics system, gives you a precise, comprehensive report on the condition of your spindles:

Monitor your spindles with IRIS to ensure their performance in production!

Witis is the reference application for defining and optimizing cutting processes and diagnosing machining equipment:

Would you like to know more? Do not hesitate to contact us…

MITIS, entreprise de technologies innovantes installée depuis 2012 à Bouguenais (Nantes), est la référence du procédé de Perçage Vibratoire, solution d’excellence pour optimiser les performances en production d’usinage.