MITIS, entreprise de technologies innovantes installée depuis 2012 à Bouguenais (Nantes), est la référence du procédé de Perçage Vibratoire, solution d’excellence pour optimiser les performances en production d’usinage.

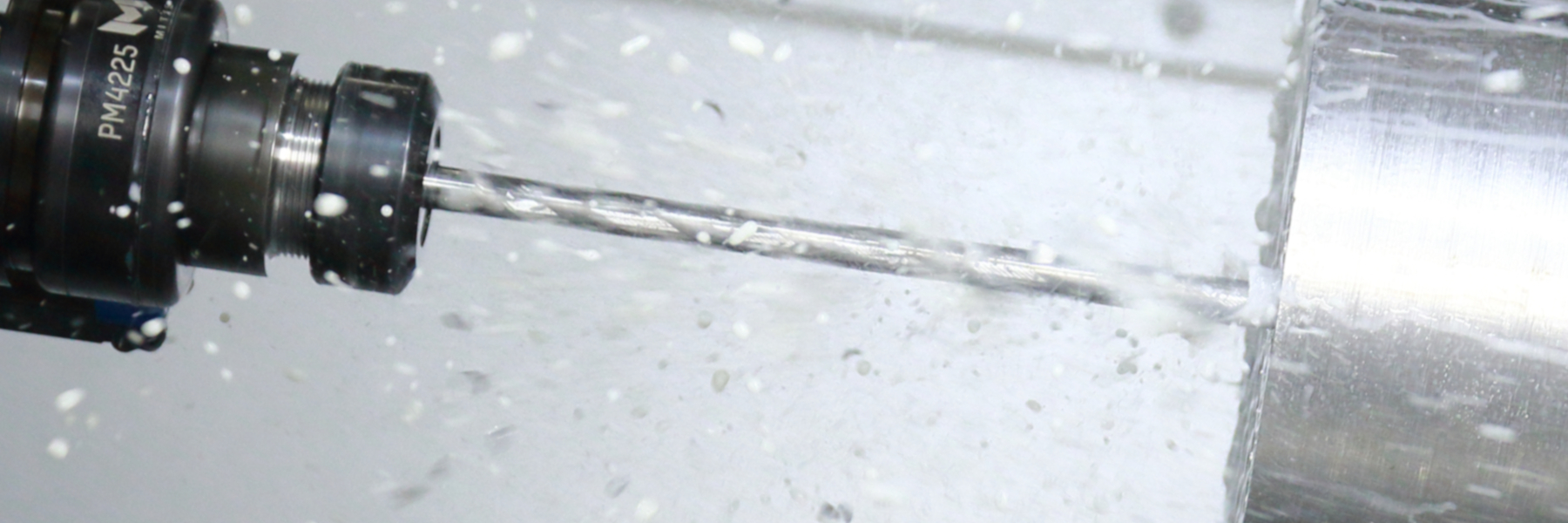

Revolutionary cutting kinematics: reliability and performance in drilling

Vibratory assistance in drilling opens up new production opportunities, unrivalled by conventional technologies.

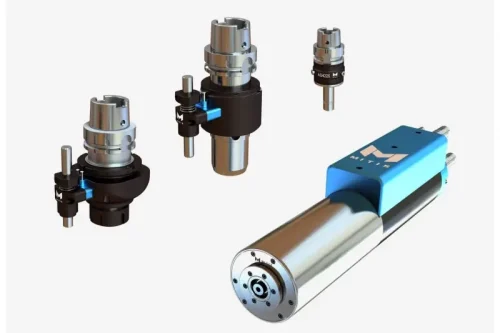

Turnkey industrial solutions to take advantage of the benefits of Vibratory Drilling on all types of equipment.

Deep holes, multi-material stacks, refractory or difficult to machine materials: the solution for demanding or critical drilling applications.

Tool-holders or spindles, mechanical or piezoelectric technology: a complete range of products for the integration of vibratory assistance on any type of means.

Would you like to know more about vibratory drilling? Contact us at +33 2 40 59 24 21 or leave us a message:

MITIS, entreprise de technologies innovantes installée depuis 2012 à Bouguenais (Nantes), est la référence du procédé de Perçage Vibratoire, solution d’excellence pour optimiser les performances en production d’usinage.