MITIS, entreprise de technologies innovantes installée depuis 2012 à Bouguenais (Nantes), est la référence du procédé de Perçage Vibratoire, solution d’excellence pour optimiser les performances en production d’usinage.

The spindle is one of the most critical component of the machining system to ensure the precision of rotation of the cutting tool whatever the cutting parameters and to transmit efficiently the cutting forces on the whole speed range.

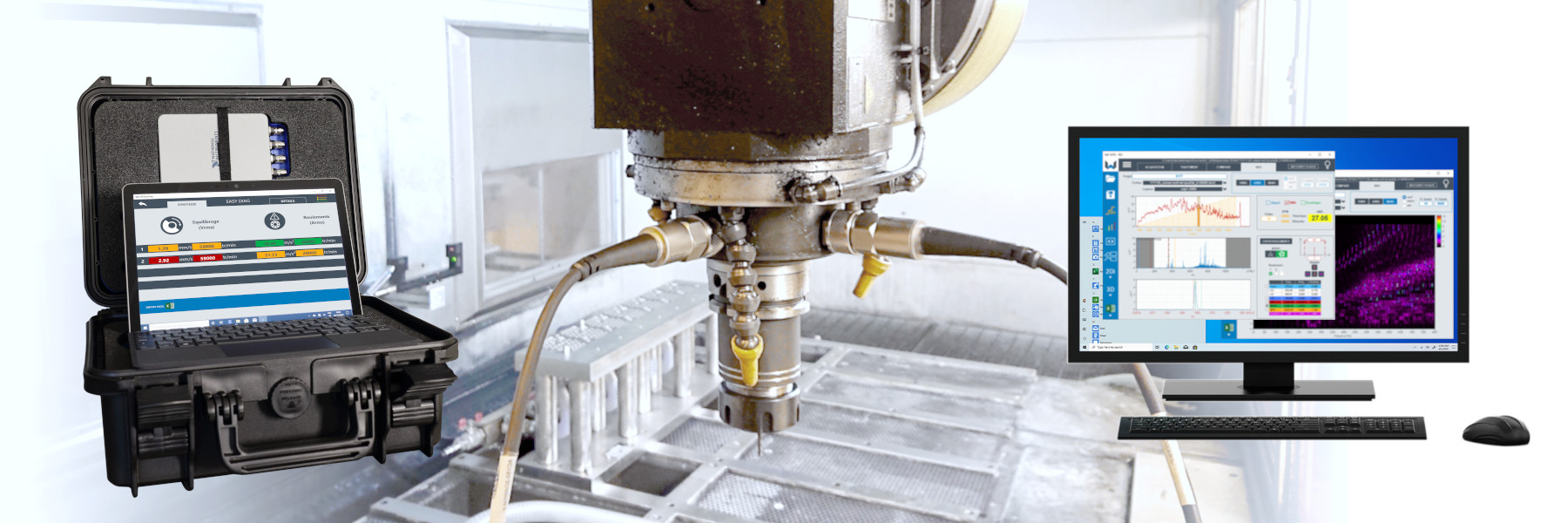

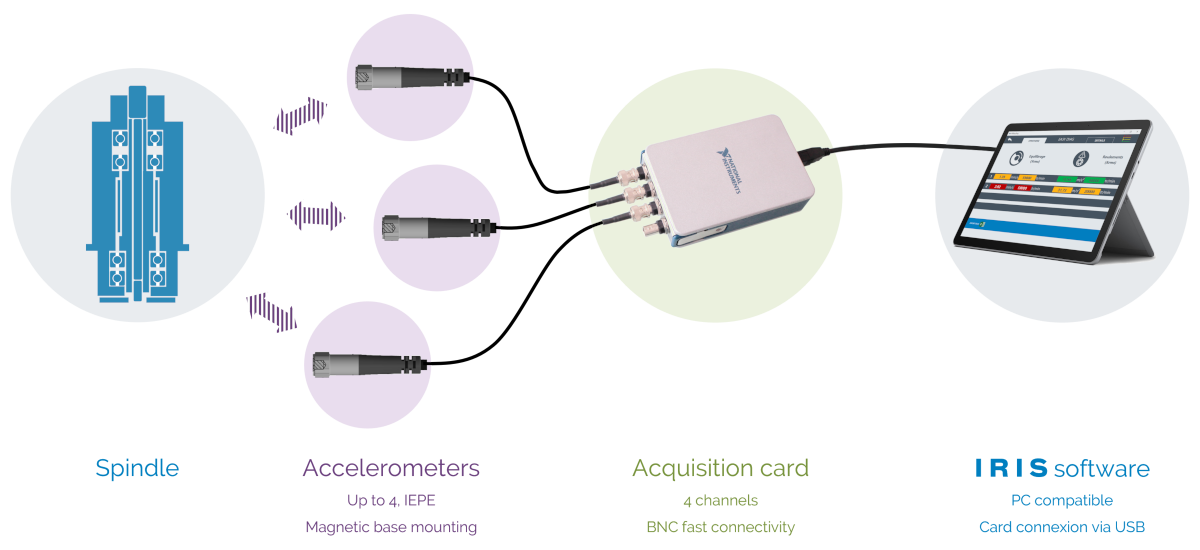

IRIS is a mobile monitoring system for the preventive maintenance of spindles by a precise and complete diagnosis:

Intuitive user experience

Fast measurement and diagnosis

Analysis assistance, Mitis hotline

… in a single application to cover all needs.

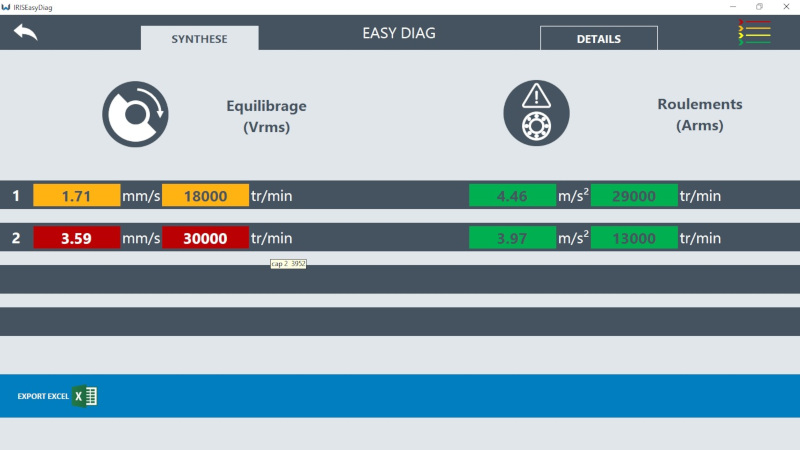

Quick access to a synthetic diagnosis of the spindle balancing and the state of wear of the bearings (criteria based on the ISO 17243 standard).

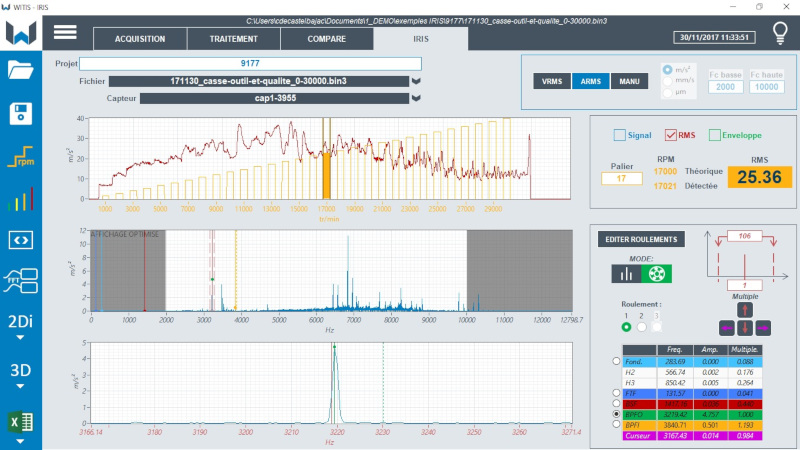

Automatic detection of the characteristic fault frequencies of each bearing to anticipate failures and improve the diagnosis.

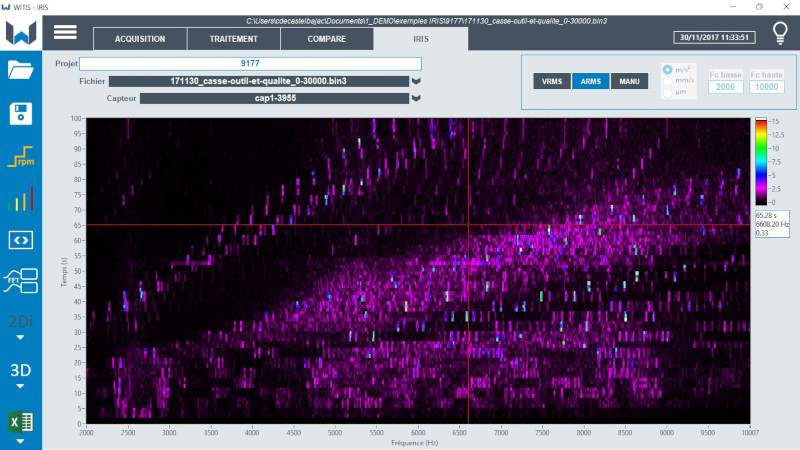

The spectrogram type representations (time, frequency, amplitude) allow a “3D vibratory vision” essential for the identification of the various spectral components related to the spindle and its environment.

Spindle designers or repairers, CNC machine-tool manufacturers, machinists: a common language to describe the condition and behavior of spindles.

Reference of the Vibratory Drilling process, specialist in axial machining processes and designer of drilling spindles, MITIS is also recognized for its expertise in the measurement and study of vibrations in machining.

Along with the IRIS system, Mitis offers a complete range of associated services:

Would you like to know more about our vibration diagnosis solutions for spindles?

Contact us at +33 2 40 59 24 21 or leave us a message:

MITIS, entreprise de technologies innovantes installée depuis 2012 à Bouguenais (Nantes), est la référence du procédé de Perçage Vibratoire, solution d’excellence pour optimiser les performances en production d’usinage.